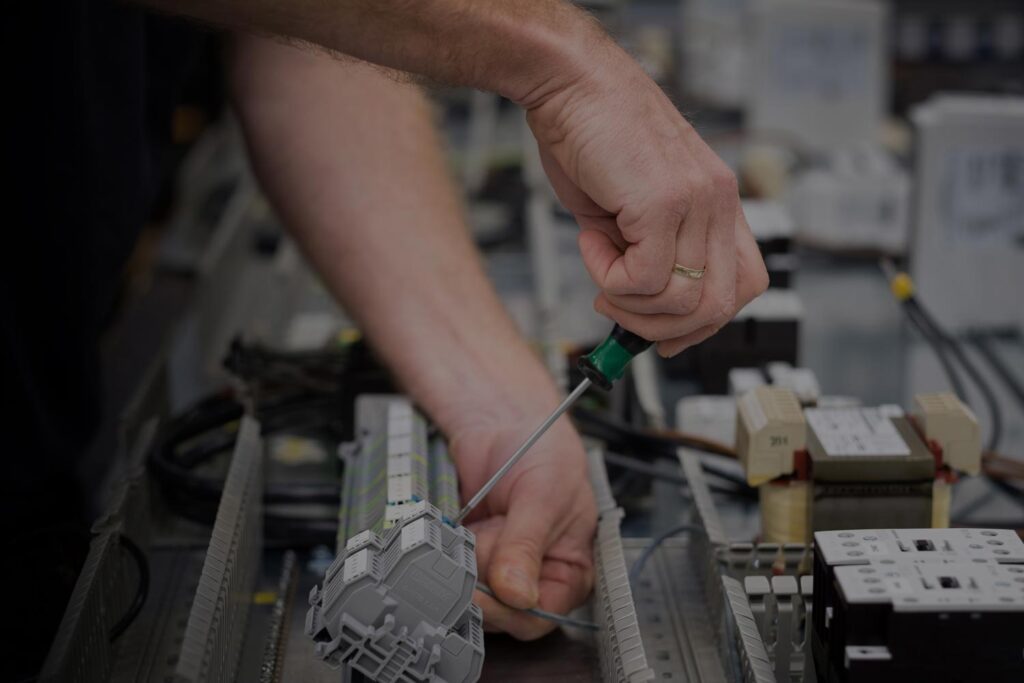

Crucially, panel construction is a broad concept. Therefore, we would like to explain some panel construction forms:

1. Serial panel construction

In serial panel construction, a large number of identical panels are made. Thanks to our attractive prices, yet high-quality electrical installations, we build larger series of panels several times a year. Thanks to our years of experience in panel construction, we know how to minimize the cost per panel and contribute to savings for you, the customer. The benefit to you as a customer is a guarantee consistent quality at the lowest possible price. If you are looking for a reliable partner for serial panel construction, then you have come to the right place.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

2. Sustainable panel construction

Sustainable panel building is a form of panel building that requires consideration of the environmental impacts of panel production/manufacturing, testing and waste. Would you like a panel to feature eco-friendly or recycled materials, for example? Or do you want us to ensure energy-efficient production? Or that the panels are powered by solar panels or wind energy? Our specialized team is at your service and always offers at the best possible price.

We believe sustainable panel construction is important, as it helps to reduce (negative) environmental impacts within the industrial sector. So as a machine builder, you can contribute to reducing emissions, saving energy and reducing climate change through the use of sustainable panels. Pleasant additional benefits include contributing to cost reductions on your customers’ energy costs, increased panel life and contributing to waste reduction.

3. Custom panel construction

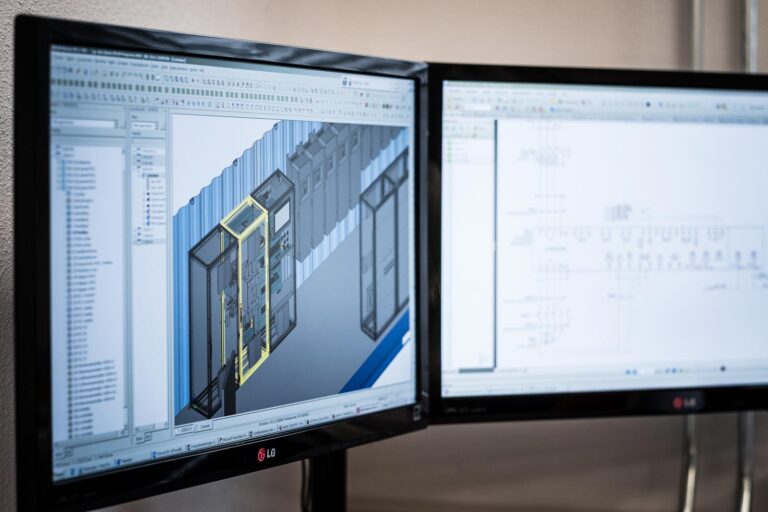

Custom panel construction is the process of engineering (conceiving) and building a custom control panel for a specific application. This involves creating unique designs that meet our client’s needs at the most favorable price. All components are well integrated and function as specified. Of course, you can also contact Gerbin Control A for a custom design.

At Gerbin Control, you can also turn to custom design.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

4. Project-based Panel Construction

Project-based panel construction is a method of teaching electrical engineering principles through project-based learning. This teaching technique is often used in high schools and universities to teach students practical knowledge about wiring and circuits.

Do you need help in the field of panel construction? Then contact us now and experience our capabilities.

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

Panels for the U.S. or Canadian market

Gerbin Control is UL/CSA listed and so we can also provide switchgear and control panels for the North American and Canadian markets under our own responsibility build and mark/certify!

UL/CSA certification is a sign of safety and quality assurance that indicates a product has been tested and certified by an accredited testing laboratory. The UL/CSA certification process includes rigorous testing that ensures the electrical panels meet the highest standards of safety and performance for the North American or Canadian market. In the countries mentioned, the focus is on fire safety, impact resistance, mechanical strength and other related safety criteria. The legislation is significantly different from European legislation. Fortunately, as a customer, you don’t have to worry about the challenges, and our expert staff knows how to handle the UL/CSA certification of your panels.

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s