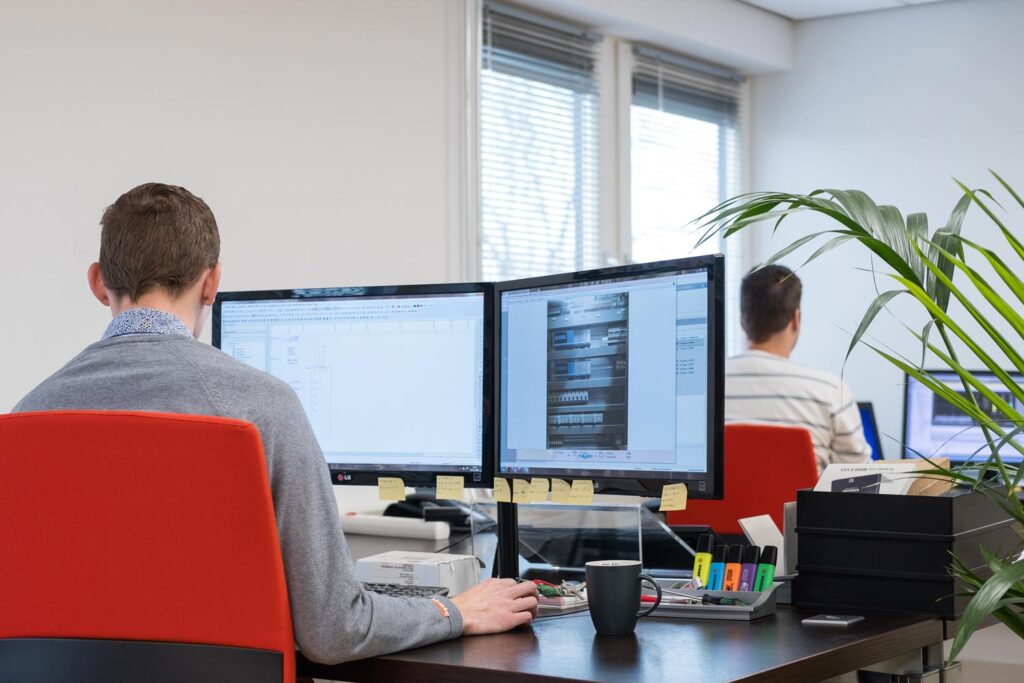

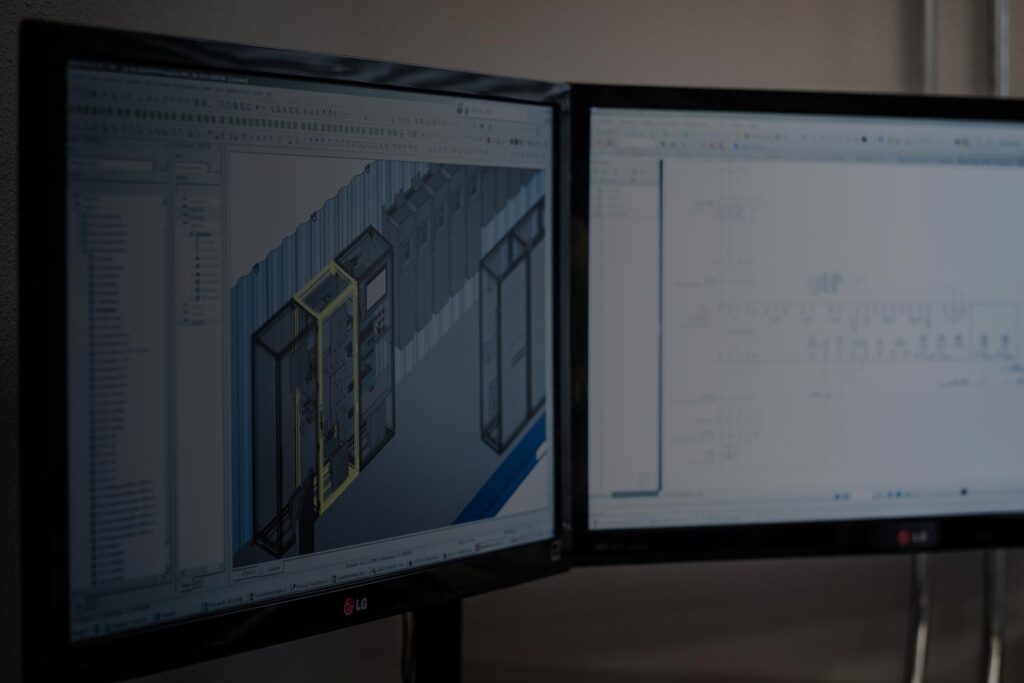

Hardware engineers bear a great obligation in the innovation and refinement of electrical installations. As a hardware engineer, you do more than just plotting out an electrical schematic using Eplan. They are responsible for electrical engineering design, testing and improvement of hardware systems, from single components to integrated systems. They work closely with software engineers and other technical professionals to develop electrical installations that are capable, competent and reliable. Programs used include AutoCAD, Eplan 5.7 and Elcad. Hardware engineers must keep abreast of the latest developments and technologies and apply them in their work to improve and elevate products. They must be resourceful problem solvers, have years of experience with Eplan and tackle technological problems to formulate goods that meet customer expectations. In short, the role of hardware engineers is essential because they are essential in shaping technologies that advance and enrich our lives.

Design and development of hardware systems

Hardware engineers are essential in the construction and creation of electronic hardware systems and electrical engineering designs. This process begins with understanding the standards and requirements of a product, then the necessary hardware engineer creates the specific components and systems.

Using technology to reproduce how the hardware setup will work is an important part, followed by prototyping for extensive review and modification. The main goal is to come up with something that works well, is competent and reliable. In addition, hardware engineers must consider aspects such as production costs, safety of goods and ecological impact when designing and developing hardware systems. The aspects such as designing and producing hardware systems are difficult parts that require engineers to have a good education, content knowledge and good training to achieve exceptional results. You can usually find these engineers at large companies that have deep knowledge and the necessary components.

The difference between hardware and software engineering

Hardware engineering is a complete package of designing, building and testing physical components, such as computers, telephones and other electronic devices. It covers a wide range of activities, from designing circuits and components to connecting electronic components and increasing efficiency. On the other hand, software engineering is the practice of creating computer programs and applications that run on hardware systems. Software engineers are responsible for writing code that allows hardware systems to perform certain tasks or functions. Although both disciplines are essential in the development of modern technology, they have different focuses.

Come work at Gerbin Control as a hardware engineer

Check out our vacancy ‘Hardware Engineer Industrial Automation’ and join the nicest team in the Netherlands.

Work in a

innovative environment

The most challenging projects

Collaborating with a team of experts

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s