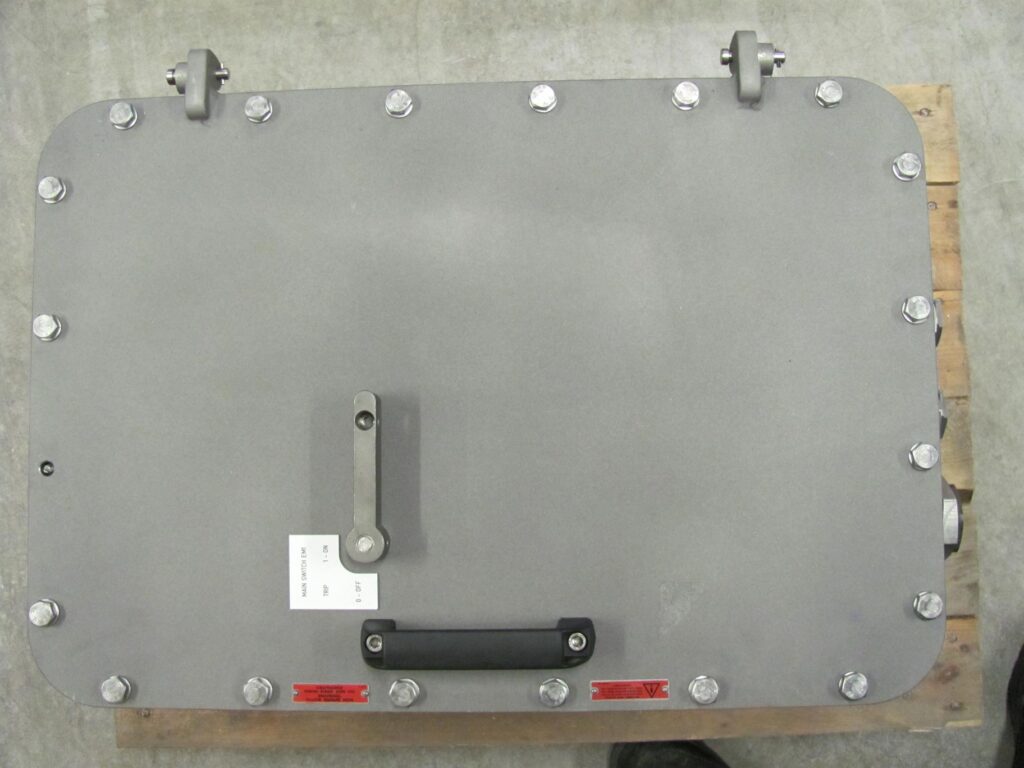

If your company works with explosive substances, in the form of gases, vapors, mists or dust then all equipment intended for use in this explosive environment will need to comply with the ATEX 114 directive (2014/34/EU) or possibly IECEx standard outside Europe.

Gerbin Control supplies explosion-proof control panels, control cabinets and terminal boxes for Zone1 and Zone2 for gas and dust environments. Depending on the area of application and the required level of safety, different types of protection can be used: increased safety (Ex e), intrinsic safety (Ex i), flameproof enclosure (Ex d) or internal overpressure (Ex p) or a combination of these.

Related Articles

Condition monitoring with PC control offshore

Smart control in a tough environment Offshore oil platforms are the nerve center of energy production at sea. But they are also extremely complex installations

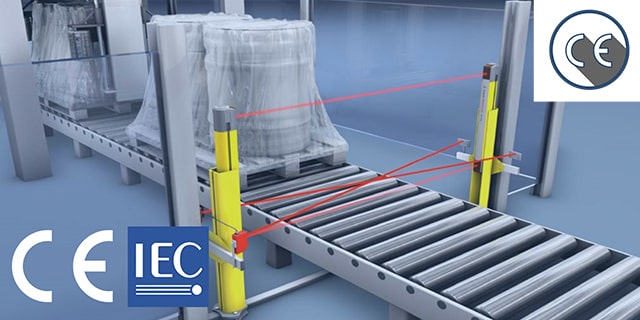

Automating intralogistics within production environments

Intralogistics as a silent engine of production and distribution Many companies focus on transportation, warehousing or shipping – but forget that internal goods flows also

Automation in water and wastewater management

The need for smart systems in water infrastructure Water management is under pressure. Due to increasing water demand, stricter environmental requirements and the need to

The critical role of safety systems in construction automation

Automation in construction requires safe control The construction industry is undergoing a rapid transformation. More and more processes are being automated: from repetitive operations to

HMI panels in the food industry

The role of HMIs within food processing Modern food processing is all about control: about hygiene, processes, safety and speed. HMI panels – Human Machine

Automation in offshore oil and gas production

Why automation is becoming indispensable at sea The offshore oil and gas industry is operating under increasingly complex conditions. As competition increases, production platforms are