SCADA systems for industrial process automation

- Real-time process insight

- Industrial reliability

- Scalable architecture

Real-time process insight and analysis via SCADA systems

SCADA systems for industrial process automation play a central role in understanding and controlling industrial processes. With a SCADA solution, data from PLC controls are collected, visualized and analyzed. This makes it possible to continuously monitor processes, quickly identify deviations and make informed decisions. Within a SCADA system industry, process visualization and monitoring PLC are central. Operators and technicians get real-time overview, while historical data is used for analysis and optimization of the plant.

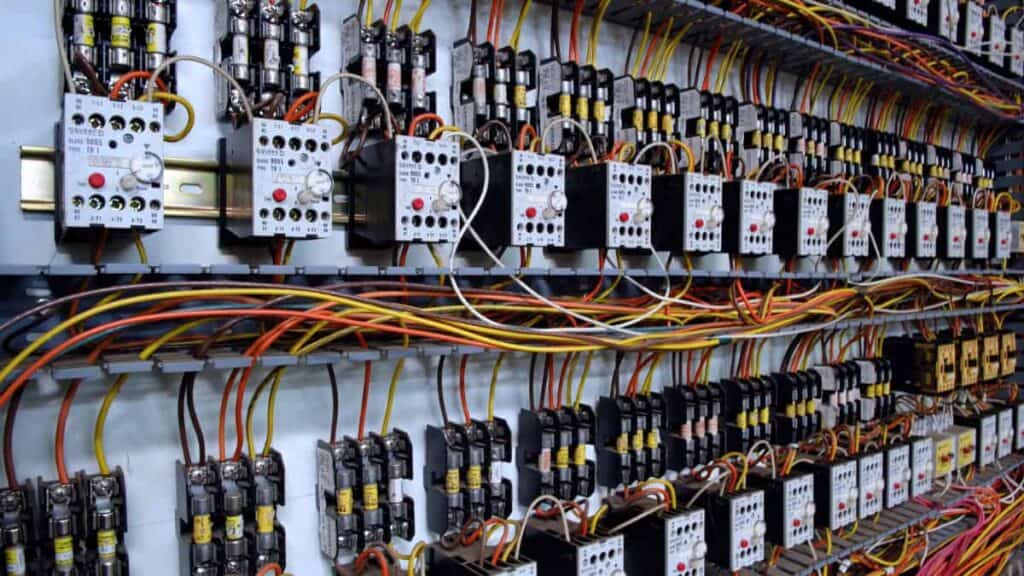

Paneelbouw Pioniers voor Machinebouw

Met de precisie van een horlogemaker en de souplesse van een acrobaat, zet Gerbin Control zich in voor het creëren van maatwerk elektrotechnische panelen voor de machinebouw. Als veerkrachtige speler in de paneelbouw, schakelen we snel, zonder in te boeten op kwaliteit of duurzaamheid. Stap in onze wereld van innovatie en ontdek hoe we uw machinebouw-projecten naar een hoger niveau kunnen tillen.

OPEN CALCULATIE

Krijg duidelijkheid in kosten en flexibiliteit in uitvoering

OFFERTE IN 5 DAGEN

Wij begrijpen de urgentie van uw projecten

VERDUURZAMING

Toegewijd aan een duurzamere toekomst

UL/CSA

UL / CSA certificering voor uw panelen in huis.

What are SCADA systems for industrial process automation

SCADA systems for industrial process automation are the upper tier above PLC controls. Whereas a PLC controls the process directly, a SCADA system focuses on process visualization, monitoring and data collection. In a SCADA system industry, process values, alarms and trends are displayed centrally. This gives operators insight into the current status of installations and makes it easier to manage and optimize processes. SCADA is used in a variety of industrial environments where continuity and reliability are essential.

Important standards and guidelines

NEN-EN 60204-1

This standard applies to the electrical equipment of machines to which PLC and SCADA are connected. It provides an important framework for safe design, construction and testing of control systems.

NEN 1010

NEN 1010 describes the safety regulations for low-voltage installations. This standard is also relevant to SCADA solutions, for example for power supplies, cabling and connection of control and visualization components.

Machine safety and PL/SIL

When SCADA systems provide information to safety functions, work is done according to PL or SIL methodology in accordance with EN ISO 13849-1 and EN/IEC 62061. This is a methodical approach to safety, not certification of the SCADA system itself.

CONTACT US

Applications in industry

SCADA systems are deployed in industries where process insight and central monitoring are critical, such as:

- Industry and mechanical engineering

- Infra and water management

- Logistics and automated systems

- Energy and process plants

Within these applications, SCADA supports process visualization, alarm management and reporting, among other things. The hardware is often housed in industrial control cabinets with appropriate IP ratings, such as IP54 or IP65 depending on the environment.

Technical construction of a SCADA system

A SCADA solution typically consists of servers, clients and communication links to PLCs. Industrial protocols such as Profinet, Modbus TCP and OPC UA ensure reliable data exchange. Functions such as user management, logging and trend analysis are standard components of monitoring PLC and process visualization.

Engineering and documentation are performed with tools such as EPLAN for a structured and maintenance-friendly setup.

Benefits of SCADA systems for process automation

Using SCADA systems for industrial process automation offers distinct advantages:

- Central overview of processes and installations

- Rapid detection and analysis of malfunctions

- Historical data for optimization and maintenance

- Better support for operators and technicians

These benefits contribute to higher operational reliability and more manageable processes.

From design to commissioning

The process starts with the functional design of the SCADA system, tailored to the process and existing PLC controls. This is followed by configuration, integration and testing. FAT and SAT are fixed steps to verify operation and reliability. After successful testing, the SCADA system is commissioned and transferred to the user.

Years of experience in the field of industrial automation

Efficiency and reliability in industrial automation

With Gerbin Control as your partner, you benefit from several specific advantages. We strive for reduced Total Cost of Ownership (TCO) and offer electrical components that meet the highest standards. In addition, we combine flexibility with competitive pricing, increase the efficiency of your systems and machines, and have an international network and UL/CSA certification.

Gerbin Control as a partner for SCADA systems in process automation

Gerbin Control supports industrial organizations in the design and realization of SCADA systems for industrial process automation. With expertise in PLC and software engineering, panel construction and commissioning, they deliver solutions that fit the practice of industrial environments. Control panels and SCADA hardware are designed and built in accordance with NEN-EN 61439 and NEN-EN 60204-1. As a UL Listed Panel Shop, Gerbin Control can also realize panels according to UL 508A for international applications. Through experience in sectors such as mechanical engineering, infrastructure and water management and logistics, Gerbin Control acts as a reliable technical partner from design to delivery.

Want to know how SCADA can contribute to better process insight? Contact us for advice or a technical exploration.

Frequently asked questions about SCADA for process automation

What is the difference between PLC and SCADA?

A PLC directly controls the process and processes signals from sensors and actuators in real time. SCADA is the upper layer that collects, visualizes and stores data from PLCs. Where the PLC provides control, SCADA provides insight through process visualization, alarm management and reporting. Together, they form the core of industrial process automation.

What does a SCADA system do in industry?

A SCADA system provides central insight into industrial processes. It displays process values, status information and alarms and enables trend analysis. Operators can thus react more quickly to deviations. In addition, SCADA supports monitoring PLC, data logging and reporting, which helps with plant optimization and maintenance.

In what industries is SCADA process automation used?

SCADA is used in sectors such as mechanical engineering, infrastructure and water management, logistics, energy and process industry. Wherever multiple installations or processes need to be monitored, a SCADA system provides overview and manageability. The solution is tailored to the specific environment and business processes.

What standards are relevant to SCADA systems?

For SCADA systems, standards such as NEN-EN 60204-1 and NEN 1010 are relevant for the electrical safety of connected systems. When SCADA plays a role in safety functions, work is done according to PL or SIL methodology in accordance with EN ISO 13849-1 and EN/IEC 62061. These standards are applied without unjustified certification claims.

How is a SCADA system tested and delivered?

Testing a SCADA system is done in several steps. During the FAT, configuration and functionality are checked before the system is installed on site. After installation, the SAT follows, during which real-world operation is tested. This ensures controlled and reliable commissioning.