At Gerbin Control, a specialist in industrial automation and panel building, the role of a panel builder is critical in the process of electrical cabinet building. Customized solutions, close collaboration and immediate impact are just a few aspects that contribute to the builder’s effectiveness. In this article, we take a closer look at the important duties and responsibilities of a panel builder and how they contribute to providing high-quality panel building solutions for industrial automation.

Table of Contents

An all-round employee with specialized duties

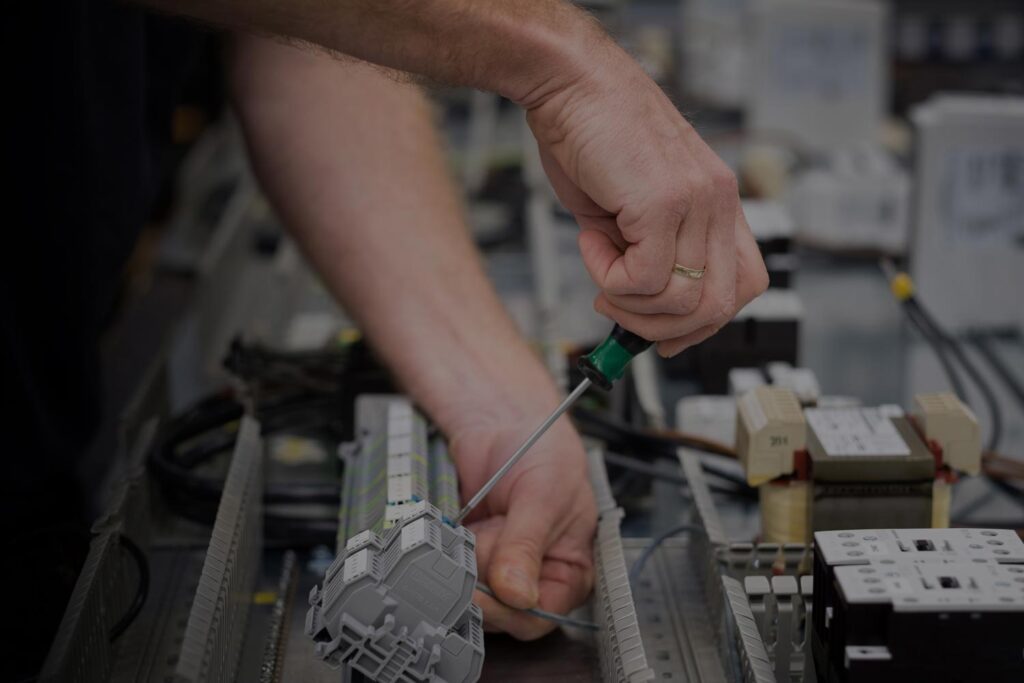

The work of a cabinetmaker is varied and requires a combination of all-round skills and specialized tasks. As a cabinet builder, some of the main duties include:

- Interpretation of electrical engineering drawings

- Selection of suitable electrical components and equipment

- Assembly and wiring of electrical cabinets

- Accurate wiring and connection of components

- Collaboration with other technical disciplines for seamless integration

- Thorough testing of cabinets to meet standards

- Focus on detail and precision for optimal performance

- Ensure quality and safety throughout the process

The cabinetmaker serves as an all-around worker who masters various aspects of the trade. At the same time, they specialize in the assembly and wiring of electrical cabinets, which is crucial for the effective operation of a variety of electrical systems and applications. Through their expertise and dedication, cabinet builders contribute reliable and high-quality cabinet solutions that meet the specific requirements of various projects and industries.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

Electrical work for custom cabinets

The importance of wiring in industrial cabinetry

One of the essential tasks of a cabinet builder is to perform wiring of custom cabinets. This includes the careful laying of custom cabling, taking into account the available space and associated wiring. The cabinet builder works closely with electrical workers to ensure that all wiring is properly installed and connected.

A customized closet: From design to realization

At Gerbin Control, each project is treated as a unique custom concept. Our cabinet makers play a crucial role in translating these concepts into reality. They work with the client and other stakeholders to understand the requirements, perform technical calculations and realize the customized concept. This requires a good sense of space and sense of perfection to ensure that each cabinet is perfectly tailored to the customer’s needs.

How important is collaboration and communication in this process?

In the process of electrical cabinet building, cooperation and communication is key. The cabinet builder works closely with other specialists, such as wiring assemblers, industrial door specialists and skilled machinists. Effective communication and teamwork allow them to handle large projects efficiently and ensure smooth execution.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

What is Gerbin Control known for?

Gerbin Control is known for its focus on innovative automation solutions. As part of the industrial automation team, we panel builders contribute to the creation of advanced systems and processes. We use our technical expertise to select the right components, perform calculations, and do the wiring accurately. This contributes to the efficiency and reliability of automated systems.

Quality and craftsmanship

At Gerbin Control, we have a team of enthusiastic specialists with years of experience in cabinetry. Our experienced cabinet makers have in-depth knowledge of different types of cabinets and specialize precisely in custom cabinetry. We can tailor the cabinets to match our client’s design and technical requirements, striving for high quality at every stage of the process.

Innovation in the technical space

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

New vacancies and junior projects

At Gerbin Control, we always have interesting new job openings and exciting junior projects available. As a panel construction mechanic, you will have the opportunity to fully utilize your technical knowledge and experience in building control panels for a wide variety of plants and machines. From an electrical drawing, you will build control cabinets, both mechanical and electrical, with accuracy and neatness. Whether you enjoy working independently or prefer to function as part of a team, at Gerbin Control we offer a stimulating work environment where you can fully develop your talents. Are you ready for this challenge? Discover our new vacancies and junior projects and take the next step in your career at Gerbin Control!

Conclusion

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s