When it comes to industrial automation and panel building, it is essential to work with reliable partners who can provide high-quality solutions that meet your specific needs. In this article, we will discuss the benefits of outsourcing panel construction to specialized companies, such as Gerbin Control. Discover why working with experienced panel construction professionals can take your projects to the next level.

Table of Contents

How does panel construction work?

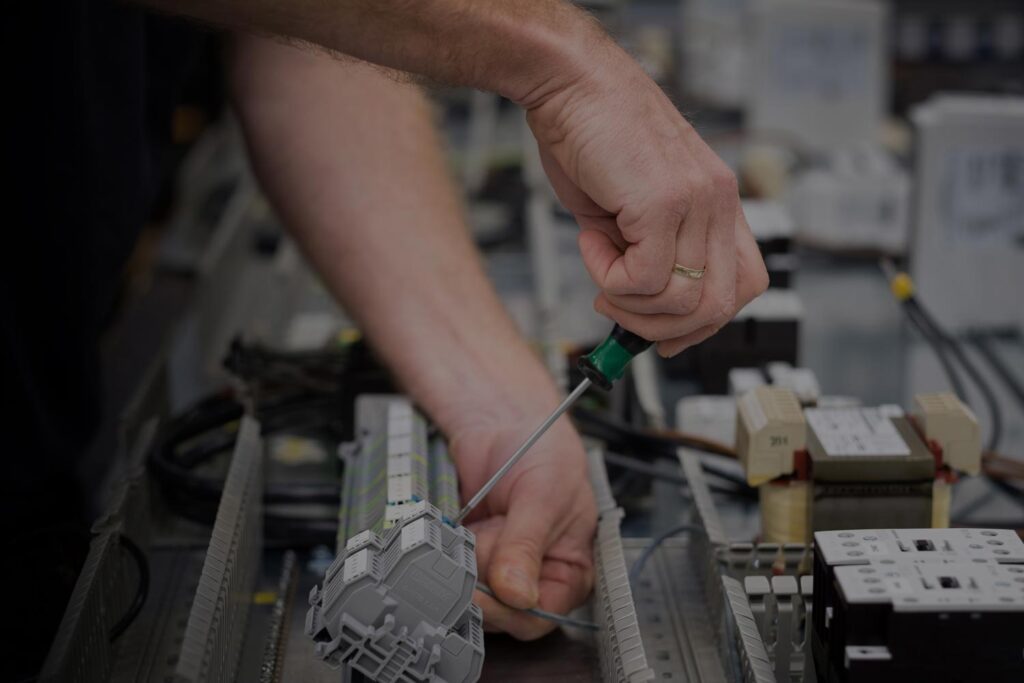

Panel construction is a meticulous process in which specialized craftsmen design, assemble and wire electrical panels and switchboards. It starts with interpreting electrical engineering drawings and selecting the right components, which is very important for the final result. The panels are then built both mechanically and electrically, with precision and cleanliness playing a crucial role. Testing the panels to meet the required standards is an essential aspect of panel construction. A specialized panel construction company can offer both project-based panel construction and custom panel construction, producing customer-specific panels and standard panels. In doing so, the panel builders use digital solutions and strive for sustainable solutions perfectly tailored to the needs of companies and installations.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

The long-term benefits

Outsourcing work to panel construction companies also offers several long-term benefits to organizations in various industries. Specialized companies have the expertise, experience and technical skills to design, build and wire high-quality control panels and switchboards. As a result, organizations can enjoy various benefits that contribute to their efficiency, productivity and long-term cost savings.

- Focus on core activities: Outsourcing panel construction work allows you as a company to focus on core activities and business strategy, while leaving the complex and time-consuming task of panel construction to specialized companies.

- Access to specialized knowledge: Panel construction companies often have a team of highly trained and experienced professionals who are up-to-date on the latest technologies and standards. As an organization, you can benefit from this specialized knowledge without investing in education and training yourself.

- Cost savings: Outsourcing panel construction work can provide cost savings in several areas. As a business, you don’t need to invest in expensive equipment, facilities or staff. In addition, panel construction companies can often offer large-scale purchasing advantages, reducing unit costs.

- Quality and Reliability: Panel construction companies strive for high-quality products and systems that meet required standards and specifications. As a result, you can rely on reliable and high-performing control solutions for their projects.

- On-time delivery: A specialized cabinet builder is experienced in planning and executing projects within tight deadlines. As a company, you can therefore count on timely delivery of control panels, allowing projects to run smoothly.

- Flexibility and scalability: Panel construction companies can adapt to the needs of different projects and organizations.

- Maintenance and support: In addition to building and installing control panels, panel building companies can also offer maintenance and support services. This ensures that the systems continue to function optimally in the long run.

- Risk reduction: Outsourcing panel construction work can reduce risks because the specialized companies have expertise and experience. This minimizes errors and complications, lowering overall project risks.

All in all, outsourcing work to panel construction companies offers a long-term strategic and cost-effective approach for you as a company in need of high-quality and reliable control solutions. By partnering with experienced panel builders you focus on core business, cut costs and benefit from high-quality systems that contribute to long-term success.

Key short-term benefits

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

Reliable partners for panel construction

Knowledge and experience in panel construction

At Gerbin Control, we have a team of experts with extensive knowledge and experience in panel construction. Our team understands the complexity of electrical installations like no other, and we have the skills to design and implement customer-specific panel building solutions. This enables us to offer your company technical support in realizing optimally designed and reliable control panels.

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

Customized service

At Gerbin Control, we strongly believe in customized service. We understand that every project has unique needs, which is why we offer flexible and customized solutions to our clients. From the first contact, we are ready to answer any questions and provide comprehensive advice. With our years of experience and knowledge to panel construction, we can design and assemble customer-specific, high-quality cabinets, with optimal design and high quality.

Our team of professionals guarantees efficient way of working and reliable solutions in building electrical panels. We strive for optimal service and offer our customers the help they need throughout the entire process of professional panel construction. By choosing Gerbin Control, our customers can rely on our expertise and high-quality results that meet their specific needs.

Conclusion

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s