In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more efficient work processes. At Gerbin Control, we see that an integrated CAD-PLM data platform is an important step in speeding up the engineering process for panel boxes. Linking systems like EPLAN to a PLM system creates one central source of truth for all design and manufacturing data.

With this approach, we shorten time-to-market, reduce errors and improve collaboration between departments.

Table of Contents

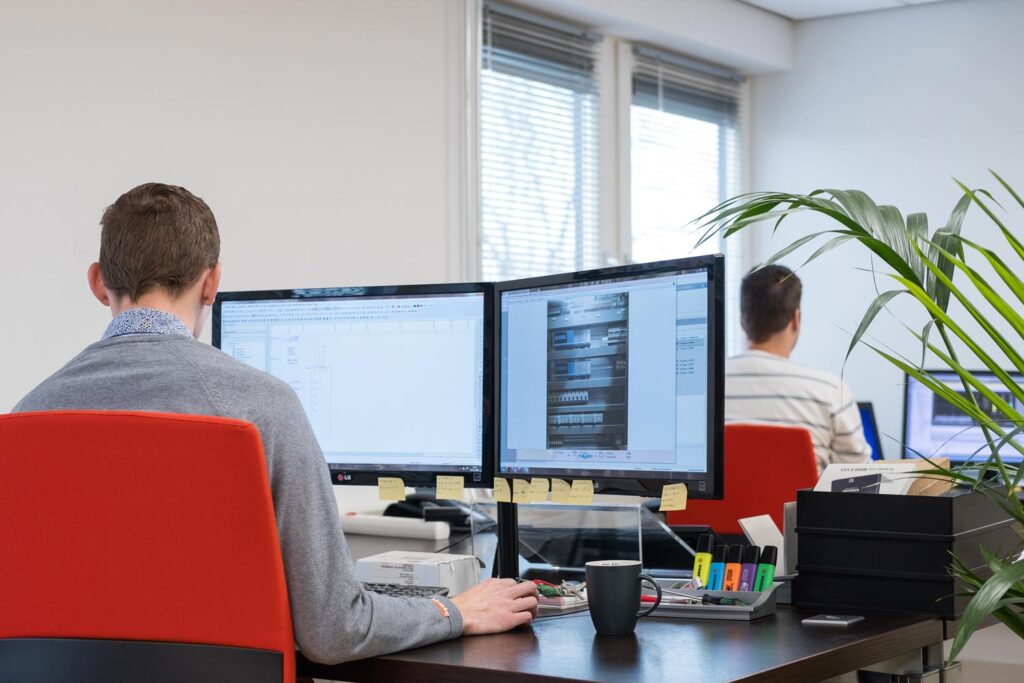

Current challenges in engineering

In many engineering environments, mechanics, electrical engineering and project management still too often operate in separate information silos. Design data is exchanged manually between different CAD systems and PDM solutions, leading to duplicate entries and a higher risk of errors.

Especially in panel building, we see that the lack of a good link between ECAD software such as EPLAN Pro Panel and other systems slows down product development. Version management of drawings, keeping parts lists up to date and complying with technical approvals takes a lot of time.

Overcoming these challenges with an integrated product data management system creates oversight and consistency throughout the product development process.

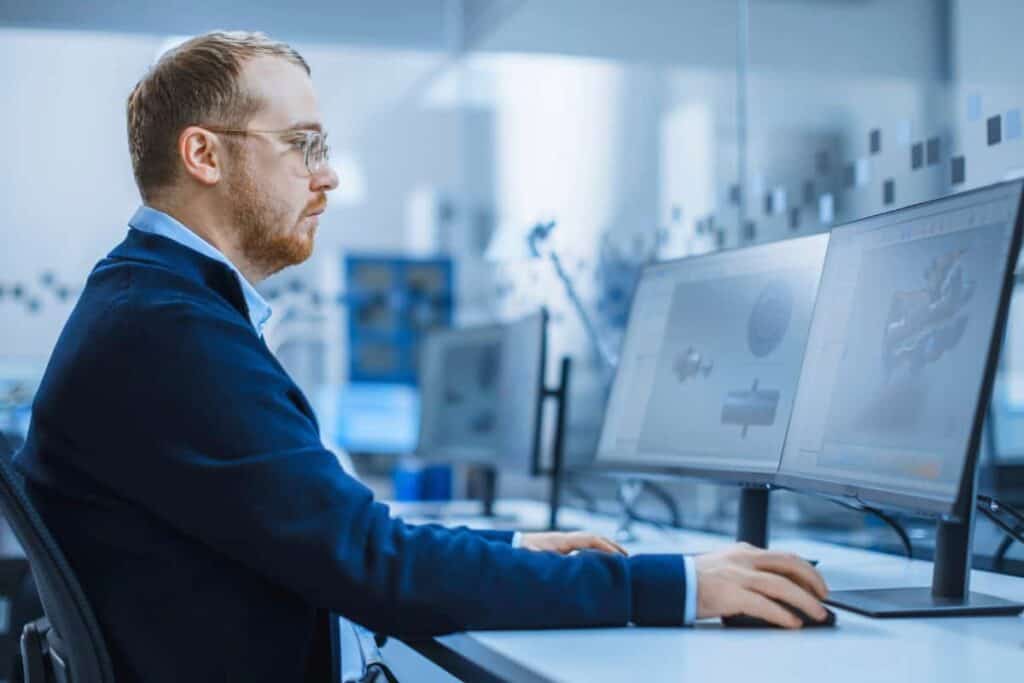

CAD-PLM integration explained

A product lifecycle management (PLM) system manages the entire life cycle of a product, from concept to maintenance. By realizing CAD integrations, all design data are directly linked to the PLM platform.

For panel construction projects, this means that changes in EPLAN, such as adding new components or modifying wiring, are automatically updated in the central Bill of Materials (BOM). Thus, all departments involved always have the correct and most up-to-date data.

At Gerbin Control, we use integrations such as the Eplan Integration Suite, which links ECAD data directly to PLM environments such as Siemens Teamcenter, Windchill or Autodesk Vault Professional. This reduces the need for manual work and decreases error proneness.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

Automatic BOM and error reduction

One of the biggest benefits of CAD-PLM integration is the automatic generation of parts lists. Where previously parts were entered manually into ERP or other management systems, this can now be exported directly from the EPLAN Electric P8 design.

This automated data exchange reduces the risk of missing or duplicate parts, and reduces preparation time in the production management process. In addition, changes can be made faster thanks to a clear change process, reducing lead time throughout the project.

Integration Examples: EPLAN and SolidWorks

At Gerbin Control, we are experienced in combining ECAD and MCAD data in one workflow. For example, we link EPLAN Pro Panel for electrical design to SolidWorks for mechanical construction.

This linkage creates a full 3D model incorporating both the electrical and mechanical aspects of the panel box. This model is then linked to the PLM system, making all item data, machining plans and drawings centrally available.

This enables faster technical approvals within the project management process and streamlines production preparation.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

Conclusion: gains in lead time

By integrating CAD systems with a robust PLM system, we at Gerbin Control achieve shorter lead times, fewer errors and higher productivity. Our customers benefit from faster delivery, better quality control and full traceability of all design and production data.

With an integrated CAD-PLM data platform, we lay the foundation for streamlined engineering, from initial sketch to delivery, and pave the way for further innovation in panel construction.

Want to know how we can speed up your engineering process for panel boxes? Contact our specialists for a customized consultation.