At Gebin Control, we recognize the revolutionary power of panel systems and their integration into the emerging world of the Internet of Things (IoT). In this article, we take you on a journey through this exciting synergy and the role we play in this transformation.

Table of Contents

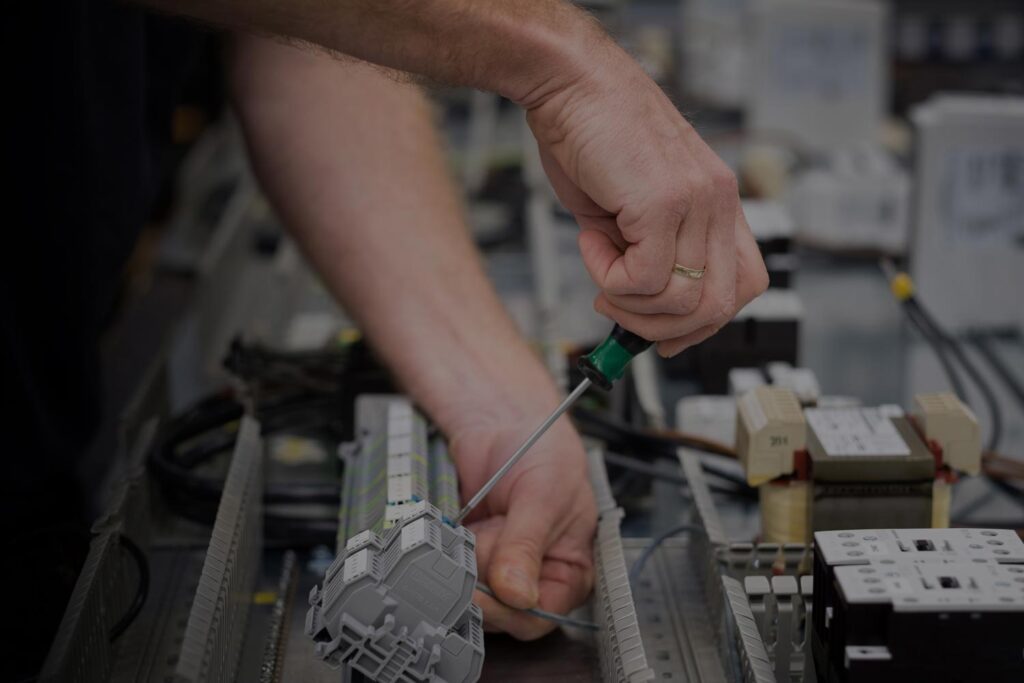

Electronic Components: The Beginning

Every panel system begins with its core elements, the electronic components. These are the building blocks that not only power our advanced panel systems but also play a crucial role in the IoT revolution. One of the most common components are variable speed drives, which manage the speed and power of electric motors. It is their ability to communicate and deliver data that make them so essential to IoT.

The Human Interface

The HMI screen and touch panels are an essential bridge between people and machines. They serve as our window into complex systems, from which we can exercise control and receive real-time feedback. For a deep understanding of how they work, we recommend you dive into the dynamics of touch panels here.

"Without an effective human-machine interface, the IoT would just be a jumble of machines with no meaningful human interaction."

Cees Brasser

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

The Role of Software and Hardware Engineering

At the heart of the Internet of Things lies a fusion of software and hardware engineering. Software brings machines to life, lets them communicate and enables us to gain valuable insights from the vast amounts of data they generate. It is also important to understand that hardware engineers are essential in this ecosystem; they make the physical connections that make all these data transfers possible.

The Physical Link

At Gerbin Control, we pride ourselves on our expertise in panel construction. Panels are the physical heart of many industrial systems, and they are also crucial to the IoT. Whether you want to understand the role of a cabinet builder or how electrical cabinetry makes industrial systems more efficient, the answers are in our comprehensive section on panel building.

In this section, we have delved into the fascinating world of panel systems and their connection to the Internet of Things. In the next section, we’ll take a closer look at SCADA systems, PLC control and the future of IoT at Gerbin Control. Keep following us for more!

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

The Deeper Connection at Gerbin Control

After exploring the basics of panel systems and their connection to the IoT, we will delve into some of the more advanced topics that drive these technologies to the forefront of modern industry.

SCADA & PLC: The Brain of the System

The Supvisory Control and Data Acquisition (SCADA) system is central to the automation of industrial processes. SCADA systems provide centralized control over various subsystems, giving operators remote access to real-time data and the ability to perform actions such as controlling machines or adjusting parameters.

Combined with PLC control, a robust and reliable method of managing machine functions, these systems form the backbone of advanced panel technology. For those wondering what exactly PLC control is, it is the technology that makes machines “intelligent,” enabling them to respond to real-time input without human intervention.

"SCADA and PLC are the invisible forces that keep our modern industrialized world running, and their integration with the IoT takes these forces to a whole new level of potential."

Cees Brasser

Software Engineering: Bringing Intelligence to the Foreground

At Gerbin Control, we understand that machines are as smart as the software that powers them. Software engineering plays a crucial role in turning raw data into actionable insights, allowing companies to make better-informed decisions. If you have ever wondered exactly what software engineering means, it is the art and science of creating software solutions that meet specific problems or needs.

Panel Construction Certification and Safety

In everything we do, safety comes first. That’s why we delve into UL certification for electrical panels, which shows that our panels meet strict safety standards. Understanding the different types of panel construction and the safety standards they must meet is essential for any industrial automation company.

Future Opportunities

The future of the Internet Of Things at Gerbin Control is limitless. With job openings such as programmer PLC/SCADA and hardware engineer industrial automation, we are constantly looking for talented individuals who can help us shape this exciting future.

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s