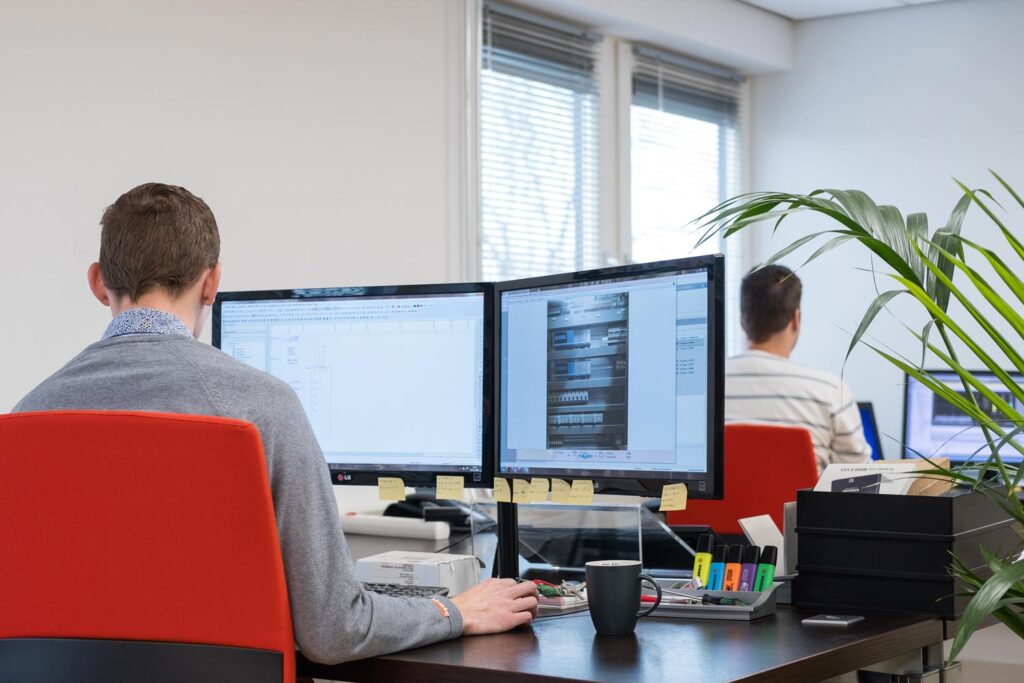

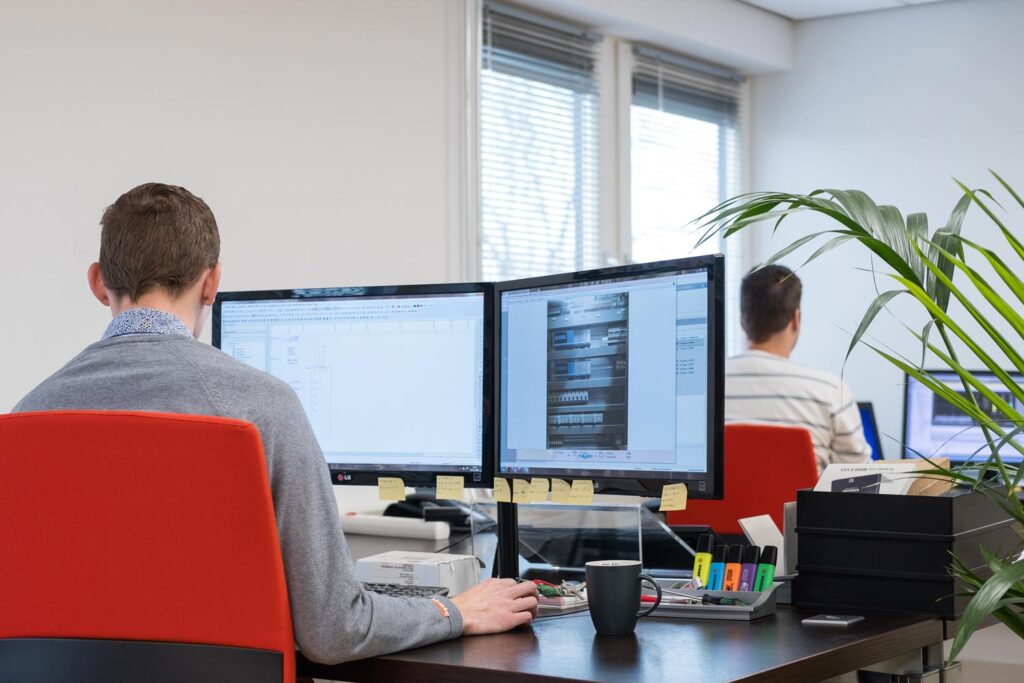

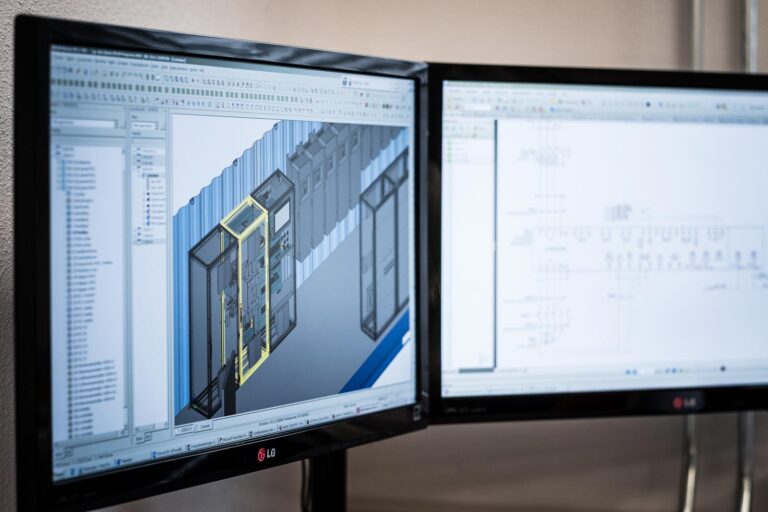

Hardware engineering is the design, generation and maintenance of hardware systems for computers and digital systems. It is a fundamental part of the technology sector and plays an important role within Industrial Automation. Hardware architects join forces with programmers to build inventive innovation for an immense scope of applications. As a hardware engineer, you are a fundamental member in the formation of new developments that improve and upgrade people’s lives. Years of experience within industrial automation contribute to consistent quality and increased efficiency.

And why is hardware engineering so important?

Hardware engineering forms the basis of our technological framework and is therefore indispensable. Cell phones, computers or advanced cars, all these things depend on hardware technology to function and be advanced. In addition, hardware engineering is also essential in creating new technologies such as machine learning, Internet of Things and robots. By better understanding and refining it, we can continue to broaden the prospects for technical progress and innovation. Read below for 3 reasons why hardware engineering is indispensable.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

1. Testing and evaluation of hardware products.

The evaluation and examination of hardware items is essential to the standard and reliability of the products being sold. This includes both internal research at the producer and external assessments by autonomous entities. This work can be done correctly with the electrical schematic. By carefully assessing hardware components, any problems and imperfections can be detected and corrected before the product arrives at the customer’s site. This increases customer satisfaction and builds confidence in the product. Also, a carefully conducted testing process ensures that hardware products perform better and last longer, improving the maintainability of the innovation area.

2. Maintain and enhance existing hardware systems.

Maintaining and improving current hardware systems is essential for optimizing the effectiveness and longevity of the electrical design. This includes normal inspections, repairs and improvements to fix problems and keep the good hardware up to date. By performing preventive maintenance procedures, you can prevent problems and avoid failures of your hardware systems. Moreover, consistent maintenance increases the speed and competence of your systems, allowing you to provide a better user experience. Ensure your hardware systems are always in optimal condition by performing standard maintenance and enhancements.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

3. Troubleshooting and solving hardware problems.

Maintaining and improving current hardware systems is essential for optimizing the effectiveness and longevity of the electrical design. This includes normal inspections, repairs and improvements to fix problems and keep the good hardware up to date. By performing preventive maintenance procedures, you can prevent problems and avoid failures of your hardware systems. Moreover, consistent maintenance increases the speed and competence of your systems, allowing you to provide a better user experience. Ensure your hardware systems are always in optimal condition by performing standard maintenance and enhancements.

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

Development within the hardware engineering industry

The hardware engineering market is flourishing at a rapid pace in response to increasing demand for modernized technologies and new products. From home appliances to complicated medical devices, the hardware industry continues to drive improvements and advances in technology and design. This contributes to new occupations and financial incentives in different areas worldwide. Moreover, the hardware industry plays an important role in refining our quality of life by developing products that support us in our daily activities. With a constant search for modernized goods and inventions, the development of the hardware industry seems far from stabilized.

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s