AC drives are crucial technologies in modern life and contribute enormously to energy efficiency and sustainability. But what exactly are variable speed drives and why are they so important? Frequency converters are electronic devices that control and adjust the frequency of an electric current to meet certain requirements. This then leads to better operation of electric motors and more productive energy consumption. Keep this definition of AC drives in mind and see how they help improve our world.

Table of Contents

History and evolution of variable speed drives

The history of AC drives goes back to the 1920s, when the first electromechanical drives were developed to change the speed of motors. In the 1960s, digital variable speed drives were introduced, which substantially improved control accuracy and reliability. Over the years, science has continued to evolve, including several new features and functions, such as superior diagnosis and correspondence. Over time, frequency converter failures have also decreased significantly. Today, variable speed drives are valuable in many industrial processes and come in different performance and cost categories (from common, low-cost drives to advanced drives with advanced features and a communication interface). The evolution of AC drives has helped the industry create more precise and energy-efficient products.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

Types of frequency converters

How are variable speed drives controlled?

Frequency converters in various applications

Where are variable speed drives used?

Industrial applications

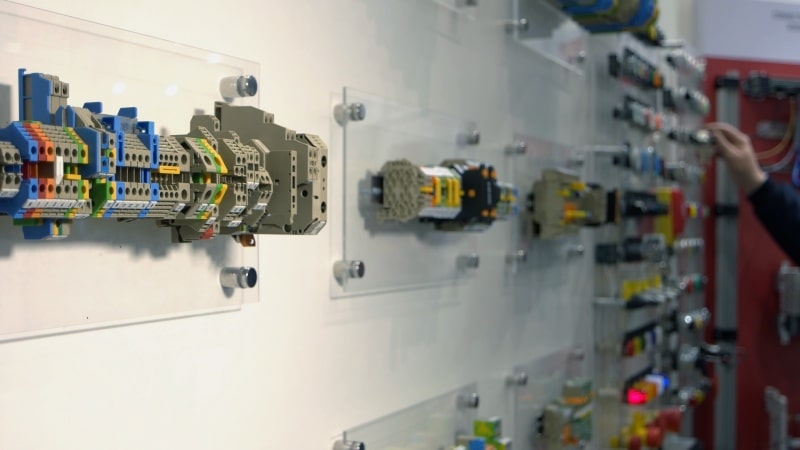

In industry, the use of AC drives is vital for optimizing performance and increasing efficiency. Variable speed drives are used to adjust the speed and power of motors and machines to meet changing production requirements, leading to increased efficiency and energy savings. In addition, AC drives can prevent machine overloads, extend machine life and reduce downtime of simple machines. Because of these advantages, variable speed drives are increasingly used in industry. This allows companies to refine their production systems and increase profitability.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

Inside homes and buildings

In homes and buildings, the use of adjustable speed drives has an important function in improving comfort and saving energy. Frequency drives are used to adjust the speed and power of heating and cooling systems according to changing needs, leading to increased comfort and energy savings. In addition, AC drives can help prevent overloading of heating and cooling systems, extend system life and reduce system downtime. Because of these benefits, the use of AC drives is gaining more ground within homes and buildings, allowing homeowners and managers to better maintain their buildings and reduce energy costs.

In the transportation sector

In the transportation industry, the use of variable speed drives is imperative to increase capacity and productivity. AC drives are used to adjust vehicle speed and power to fluctuating driving conditions, resulting in increased fuel efficiency and better operation. In addition, AC drives can help prevent motor overload, extend vehicle life and reduce vehicle downtime. Because of these benefits, the acceptance of AC drives in the transportation industry is being experienced, allowing companies and government organizations to make their transportation processes more effective and sustainable. Whether for trucks, trains, ships or other transportation equipment, AC drives play a vital role in improving the performance and efficiency of the transportation industry.

Energy and water management

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

In agriculture

Related Articles

From panel to platform: how IoT and control cabinets provide real-time machine insight

In the world of industrial automation, control cabinets are the backbone of efficient and effective production processes. At Gerbin Control, we understand the critical role

Predictive maintenance in control panels: increasing data-driven reliability

The world of industrial automation is all about continuity and reliability. Unplanned machine downtime can lead to high maintenance costs, lost production and reduced product

Machine-as-a-Service (MaaS): designing panels for flexible business models

There is a clear trend in today’s machinery industry: from traditional product sales to service-oriented contracts. The Machine-as-a-Service (MaaS) concept allows customers to pay for

CSRD & sustainability: designing circular control cabinets

At Gerbin Control, we see sustainability and responsible use of materials playing an increasing role in mechanical engineering. With the advent of the CSRD (Corporate

Integrated CAD-PLM data platform: engineering of panel boxes accelerated

In the manufacturing industry, the pressure on design engineers and project managers is increasing. Shorter delivery times, higher quality standards and stricter regulations require more

Servitization: upgrading panels in the field, wave-by-wave

In the mechanical engineering industry, thinking is increasingly shifting from just delivering products to offering ongoing value. Servitization is a good example of this. It’s