Weighing and dosing automation

- Precision to the gram

- Full traceability per batch

- Scalable and recipe-driven system

Precise weighing and dosing technology for industrial processes

Weighing and dosing automation is the automated weighing and dosing of raw materials, semi-finished or finished products within industrial processes. It is a crucial component in sectors where accuracy, reproducibility and speed are decisive for product quality – such as in the food industry, chemicals, pharmaceuticals and bulk processing.

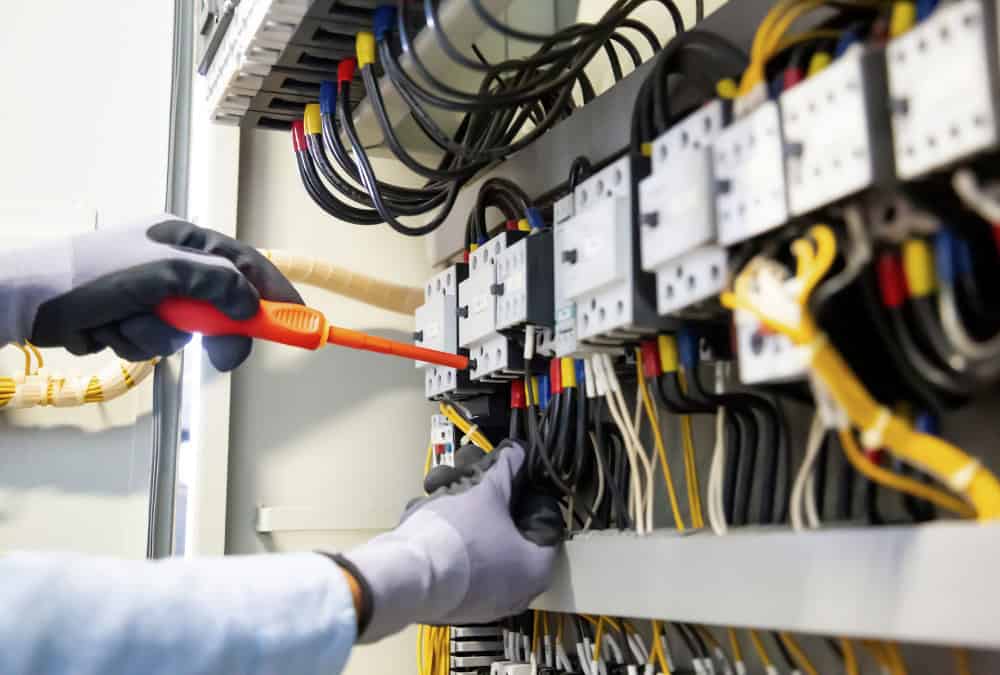

Gerbin Control designs and realizes advanced custom weighing and dosing controls. Our systems accurately control scales, dosing screws, valves and vibrating chutes, ensuring stable and efficient processing – fully integrated within the broader production process.

OPEN CALCULATION

Get clarity in cost and flexibility in execution

OFFER IN 5 DAYS

We understand the urgency of your projects

SUSTAINABLE

Committed to a more sustainable future

UL/CSA

UL / CSA certification for your home panels.

Efficiency and reliability in industrial automation

With Gerbin Control as your partner, you benefit from several specific advantages. We strive for reduced Total Cost of Ownership (TCO) and offer electrical components that meet the highest standards. In addition, we combine flexibility with competitive pricing, increase the efficiency of your systems and machines, and have an international network and UL/CSA certification.

Application of weighing and dosing automation

Automatic weighing and dosing systems are used in formulating recipes, filling packages, loading silos or controlling mixing plants. Small deviations in weight or dosage can directly affect product quality, cost price or traceability.

Gerbin Control systems provide precise control of the entire process: from raw material input to final dosing. In doing so, we process signals from load cells, level sensors and flow meters, and control dosing elements based on set recipes or real-time feedback – quickly, reliably and error-free.

Years of experience in the field of industrial automation

Custom engineering and manufacturing

Each application places different demands on the speed, capacity and accuracy of the weighing and dosing process. That’s why Gerbin Control develops each system completely customer-specific. We take into account the properties of the product (such as flow, moisture, or density), the desired batch sizes, and integration with the rest of the installation.

Our systems are designed in EPLAN, built with high-quality components and tested for accuracy, speed and repeatability. Whether a single dosing unit or a complete line with multiple weighing points – we provide a reliable and maintenance-friendly solution.

Prescription-driven and fully traceable

Our control systems make it possible to work with digital recipes, adding each raw material with the correct sequence, speed and quantity. The systems automatically record weights, batch data and deviations. This creates full traceability and support for quality controls or audits.

Fast, accurate and reproducible

By using fast I/O modules, accurate measurement processing and direct control of dosing equipment, we can work with minimal tolerance. Even with fast cycles or small quantities, accuracy is maintained. The system can automatically correct, fill, re-dose or sort out if working outside specifications.

Easy to maintain and flexible

Our weighing and dosing systems are built with flexibility and ease of maintenance in mind. Panel layouts are clear, signals are easy to trace and the software is modular. As a result, changes, upgrades or recipe adjustments can be made quickly and easily, without complex programming.

CONTACT US

Write your message

Address

Frequently asked questions about weighing and dosing automation

What is the difference between weighing and dosing in an automated system?

Weighing is determining the exact weight of a product, while dosing is the controlled addition of a quantity of product. In an automated system, these functions work together: a dosing device (such as a screw, valve or vibrating feeder) is controlled based on the measured weight. Once the set target weight is reached, the system stops or performs fine dosing for maximum precision.

What industries does Gerbin Control supply these systems for?

Our systems are used in the food industry, feed production, chemicals, pharma and bulk processing, among others. Think of the weighing of flour in bakeries, the dosing of additives in plastic production, or the mixing of batches in the chemical sector. Each system is tailored to the specific characteristics of the product and the production process.

How is accuracy guaranteed in the system?

Gerbin Control works with high-quality load cells, fast measurement processing and accurate control of the dosing elements. In addition, we implement correction logic in the software: the system learns from previous measurements and adjusts if necessary. Fine control (coarse/fine dosing) is also possible to stay within tight tolerances, even in fast operating installations.

Can multiple components be weighed and dosed simultaneously?

Yes, our systems can control multiple weighing channels or dosing units. This makes them suitable for applications where different ingredients or components are processed simultaneously in a batch. Each channel can be calibrated and controlled separately, while the data is managed centrally for optimal traceability.

Is all information logged and available for quality control?

Absolute. Weight, batch number, recipe data and any discrepancies are logged and can be accessed via HMI or SCADA. This data is essential for quality control, validation and reporting in audits or certification. We tailor this to the desired requirements within your sector or customer-specific standards.

Are the systems expandable or adaptable in the future?

Yes, our systems are designed to be modular. That means you can easily add additional dispensing channels, new recipe functionality or customized weighing strategies later without having to replace the entire system. We build flexibly, with scalability and long-term deployment in mind.