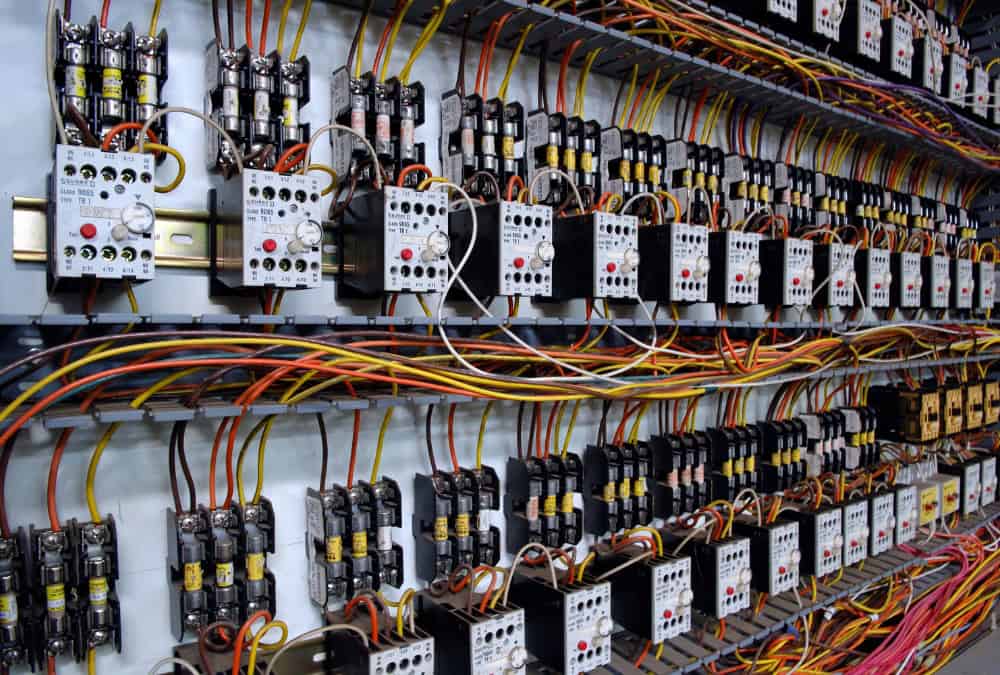

Vacuum system control panels

- Stable custom vacuum control

- Seamless integration with process control

- Reliable under all conditions

Vacuum system control: precision and control in suppression applications

Vacuum system control panels are control solutions for systems that work with negative pressure or vacuum technology. These systems are used in production processes where air or gas needs to be exhausted, controlled or regulated – such as packaging lines, suction systems or laboratory equipment.

Gerbin Control designs and builds custom vacuum control panels tailored to the functional requirements of the process and the technical specifications of the installation. Our systems ensure stable and safe operation of pumps, valves and measuring instruments in vacuum applications, with maximum control of pressure levels.

OPEN CALCULATION

Get clarity in cost and flexibility in execution

OFFER IN 5 DAYS

We understand the urgency of your projects

SUSTAINABLE

Committed to a more sustainable future

UL/CSA

UL / CSA certification for your home panels.

Efficiency and reliability in industrial automation

With Gerbin Control as your partner, you benefit from several specific advantages. We strive for reduced Total Cost of Ownership (TCO) and offer electrical components that meet the highest standards. In addition, we combine flexibility with competitive pricing, increase the efficiency of your systems and machines, and have an international network and UL/CSA certification.

Application of vacuum control in industrial processes.

Vacuum technology is used in industries as diverse as food processing, pharmaceuticals, semiconductor manufacturing, plastics processing and laboratories. Each process has different requirements for controlling pressure, flow and timing.

At Gerbin Control, we develop control systems that match this exactly. Our panels control vacuum pumps, control valves, sensors and safety devices in one integrated system. In doing so, we ensure accurate and reproducible control of negative pressure, essential for process quality and safety.

Years of experience in the field of industrial automation

Custom engineering and manufacturing

Every vacuum application requires a different approach. This is why Gerbin Control only provides customer-specific control solutions. We tailor the design to factors such as desired vacuum depth, switching frequency of pumps, valve control and required process safety.

Our engineers work with EPLAN to create an accurate electrical design, fully tailored to your installation. During construction, we use high-quality components, and perform extensive testing for leak tightness, switching speed and pressure response – all to ensure the system functions flawlessly within your application.

Integration with process and measurement systems

Our vacuum control systems easily interface with existing automation platforms. Via digital or analog interfaces, the system can communicate with central PLCs, SCADA or local control. The readout of vacuum sensors, flow meters or pressure transmitters is also fully integrated.

This creates a clear and centrally controllable system that moves with your process and responds quickly to changing conditions or settings.

Constant reliability and accuracy

Vacuum processes require controls that work quickly and precisely, without deviation or delay. Our systems are designed for constant reliability and minimum tolerances. By using high-quality control technology, fast switching and direct feedback, we ensure stable vacuum – even with varying loads or complex cycle arrangements.

Ease of maintenance and durability

Gerbin Control builds control panels that are not only functional, but also maintenance-friendly. A logical internal structure, clear labeling and access to components make inspection and service easy.

The durability of our systems is in both the hardware and the software: everything is designed for long-term operation with minimum failure susceptibility, resulting in lower costs and maximum availability of your vacuum system.

CONTACT US

Write your message

Address

Frequently asked questions about vacuum system control panels

What does a vacuum system control panel do?

A vacuum system control panel controls the vacuum pumps, control valves, sensors and safety devices within a system that uses negative pressure. It ensures precise control of the pressure level, monitoring of system values and safe switching of components. This keeps the vacuum process stable, reproducible and tailored to the technical requirements of the application.

In what industries are these control panels used?

Gerbin Control supplies vacuum controls to customers in the food industry, packaging, pharmaceuticals, plastics processing and high-tech manufacturing, among others. Think of processes such as vacuum packaging, degassing, material handling or laboratory applications where stable negative pressure is essential for quality or accuracy.

Can the system be combined with other automation?

Yes, our panels can be fully integrated with existing PLC systems or SCADA platforms. We ensure good communication between the vacuum system and other parts of the process, for example via Profinet, Modbus or analog signals. This creates one clear entity that can be centrally controlled and monitored.

How accurate is the pressure control in these systems?

Our systems are designed for high precision. Direct feedback via sensors, fast control electronics and smart control logic allow us to control and maintain pressure levels very precisely – even with sudden changes in load or process demand. This makes them suitable for applications with tight tolerances or high quality requirements.

How is the reliability of the system guaranteed?

Reliability starts at the design stage. We use only industrial components from proven brands, build according to applicable standards and subject each panel to a full function test. We also provide clear documentation and, if required, offer installation and commissioning support.

Robust construction and preventive design ensure that our systems will run trouble-free for years.

Can the system be easily maintained or modified?

Sure. Our panels are clearly laid out, with easily accessible components and clear diagrams. This allows maintenance work to be carried out quickly and safely. We also take expandability into account in the design, so that future modifications to the system can easily be made – without having to overhaul the entire installation.