Powder coating control systems

- Tight finish, stable processes

- Seamless interfacing with existing lines

- Energy efficient and safe design

Advanced controls for powder coating plants

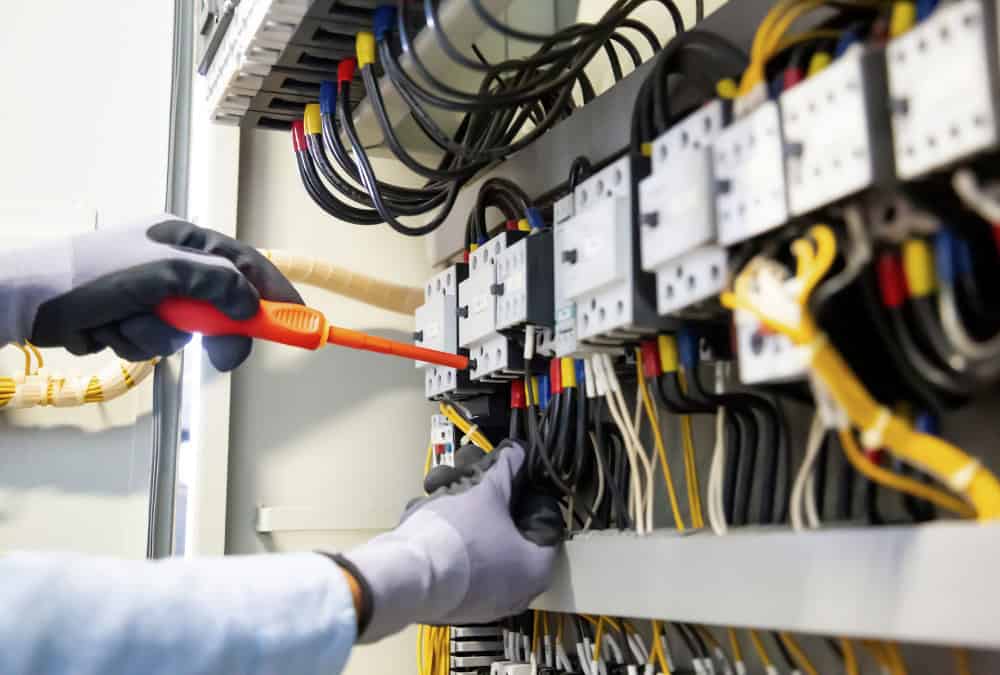

Powder coating control systems are control solutions for industrial powder coating systems, in which electrostatically charged powder is used to apply a high-quality finish to metal parts. These systems control all phases of the coating process, from pretreatment and spraying to oven curing.

Gerbin Control develops and builds custom control panels for powder coating lines, focusing on consistent finish quality, minimal waste and maximum process reliability. Our systems are designed to work flawlessly with your existing equipment and seamlessly match the technical requirements of modern paint lines.

OPEN CALCULATION

Get clarity in cost and flexibility in execution

OFFER IN 5 DAYS

We understand the urgency of your projects

SUSTAINABLE

Committed to a more sustainable future

UL/CSA

UL / CSA certification for your home panels.

Efficiency and reliability in industrial automation

With Gerbin Control as your partner, you benefit from several specific advantages. We strive for reduced Total Cost of Ownership (TCO) and offer electrical components that meet the highest standards. In addition, we combine flexibility with competitive pricing, increase the efficiency of your systems and machines, and have an international network and UL/CSA certification.

Application of control technology within powder coating lines

A properly functioning powder coating plant requires precise coordination between different process components. Consider the conveyor line, cleaning stations, spray booths, filter units and curing ovens. Failures or inconsistencies in this chain can lead to production downtime or irregular coating results.

Gerbin Control provides integral control and monitoring of all subsystems within the powder coating line. This ensures optimal sequence, timing and interaction between process steps. We also provide alarms, fault detection and real-time feedback so operators can intervene immediately in case of deviations.

Years of experience in the field of industrial automation

Custom engineering and manufacturing

Each coating line is unique and requires a solution that fits its specific layout, capacity and product specifications. We therefore design fully customized control panels tailored to your plant, your product flow and your desired level of automation.

In the design, we consider voltage zones, safety systems, temperature controls, spray time settings and conveying speed. The systems are built with reliable industrial components and are easy to interface with existing PLCs, SCADA or control panels. Everything is worked out in EPLAN and extensively tested in advance for functionality and safety.

Full line integration and optimization

Our controls ensure smooth cooperation between all parts of the powder coating line. From sensing the product on the job to automatically starting the spray cycle and controlling the oven temperature, each part of the process responds exactly as needed for a tight, even finish.

By setting parameters centrally and working recipe-driven, flexibility is increased and the risk of errors is reduced – even with changing product series or complex shaped parts.

Consistency, safety and energy conservation

The goal of a good powder coating control system is not only a neat coat of paint, but also a stable, safe and energy-efficient process. Our systems monitor temperatures, power consumption and ventilation flows, and automatically shut down parts of the plant in case of inactivity or malfunction.

This contributes not only to safety, but also to sustainability and lower operating costs – without sacrificing paint results or speed.

Maintenance-friendly and future-oriented design

As with all our control solutions, accessibility and ease of maintenance are key. The panels are clearly laid out, with clear cabling and logical grouping of functions. This makes fault diagnosis easier and maintenance quicker.

Moreover, we build modularly, so that future expansions or modifications can be effortlessly integrated, for example, when expanding a spray booth or adapting conveyor systems.

CONTACT US

Write your message

Address

Frequently asked questions about powder coating control systems

What does a powder coating control system do?

A powder coating control system controls and monitors the entire powder coating process, including such components as the conveying mechanism, spray booths, ventilation, filtration, pretreatment and curing oven. The system ensures a consistent process sequence, accurate timing and optimal settings so that each product is finished evenly and reliably.

What applications are these systems suitable for?

Our systems are used in industrial powder coating plants for metal products such as structural parts, fencing, sheet metal, machine frames and automotive parts. For both automatic and semi-automatic lines, we provide reliable control that matches production volume, line speed and quality standards.

Can the system be integrated into an existing installation?

Yes. Gerbin Control designs systems that easily interface with existing equipment, PLC networks and SCADA environments. We analyze the current installation and provide a smooth implementation, preserving your existing hardware and infrastructure as much as possible.

How does automation contribute to paint consistency?

Automating spray times, electrostatic voltage, conveying speed and temperature control provides accurate and repeatable process control. This minimizes variations in coating thickness and adhesion. In addition, we use recipe-driven settings so that the correct parameters are always applied during product changes.

How are safety and fault handling handled?

Our systems are equipped with safety relays, alarms and automatic shutdown in case of malfunctions or unsafe conditions. Think overheating, ventilation errors or blocked transport lines. This prevents damage to products, equipment or personnel and reduces the risk of downtime.

Does Gerbin Control also provide service and support after completion?

Yes, we support our customers during and after delivery with documentation, instruction and technical assistance. We can also provide service for system modifications or upgrades, and provide clear electrical schematics and maintenance information. Your coating line will continue to perform optimally, even in the long term.